D-Tek FuZion

Cost: £37.99 (inc. VAT)One of the most interesting upsets in watercooling has been caused by none other than the guys over at D-Tek Customs. D-Tek has been around a while, churning out cooling ideas since the founding days of bit-tech in 2001. Through most of watercooling history, the company was regarded as big on ideas, but largely low on performance.

That's not to say that the blocks were of poor design – it simply meant that they did not perform the way that blocks from companies like Danger Den or Swiftech did. But, D-Tek got a chance to change its name with the release of the FuZion, which is widely accepted as the currently best-performing block on the market.

What makes the FuZion so spectacular? Well, I wasn't really sure myself – until I opened it up. The D-Tek FuZion, much like the Aquacomputer Cuplex XT, is a three piece block. The top plate contains nothing but the jets. It's the bottom and middle sections we're interested in.

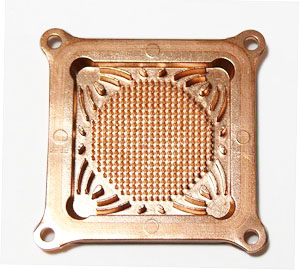

Left: The D-Tek FuZion baseplate; Right: The block's rather plain-looking Delrin midsection.

The base of the FuZion is a rather intriguing design. Over the entire CPU heat-spreader, the thin (1/4") copper is milled with a grid pattern. Water sprays down directly from the centre inlet, being forced outward to the edges. On the edges, the block's milling changes to flutes that guide the water, re-instilling laminar flow before the water flows up into the midsection of the block.

Notice that all four corners flow upwards to the midsection, which has nothing else to it – it is simply a chamber. The idea is to separate the turbulent and laminar flow sections of the block, encouraging all water in the copper base to be turbulent. This way, the midsection can function to both balance the pressure (controlled by the size of the corner holes) and reorganize the water's flow without compromising the turbulent sections.

Since the midsection is Delrin instead of metal, there is no heat transfer taking place here – allowing the water flow to organise without transferring heat back into the block. Once set in the flow, the water can quickly exit through the outlet barb located over one of the corners. The whole configuration creates a brilliant balance of pressure to allow an effective, rapid and orderly exchange.

So, could the best performing block be made better? Well, all things can. I'd probably start by a bit of turbulence heading into the block—note that there are neither nozzles nor much to induce truly turbulent flow as the water enters the block—it's a straight shot from the hose to the copper.

EK Supreme

Cost: £34.99 (inc. VAT)EK blocks have recently begun making quite a name amongst enthusiasts, with some very well-designed high flow achievements. The Supreme block, which is the latest release, is one of the most unusual designs we feature here today. The whole block is a bit paradoxical, looking like a criss-crossing mish-mash of fins and slits. And it works – well.

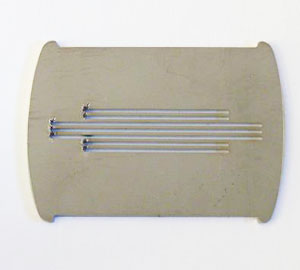

Left: The EK Supreme baseplate is neatly divided by 49 fins; Right: The cross-bar provides some interesting turbulence patterns.

The baseplate of the EK Supreme is elegantly simple – nothing more than 49 separate long, razor-thin fins. It is surface area maximisation to the extreme, and the lack of a grid pattern means that water must travel down the length of each narrow slit. This means lots of contact – but it also can mean lots of boundary layer.

However, the rather unusual mid-section helps account for this - think of it as a jet nozzle on steroids. The seven long slits lay across the fins, producing a perpendicular flow that increases turbulence by a lot. Because of the narrow aperture and the length of the slits, the Delrin top is moulded with a chamber across the length – making sure water flows into each channel in the copper base.

The channels empty out into the smooth edges of the block, where they reach an outlet barb on one side. This helps restore laminar flow to create an orderly exit – though it's not quite as well designed in this respect as the Danger Den MC-TDX and certainly not the D-Tek FuZion.

The real problem is that the area where laminar flow re-forms creates a current. Since the channels exit on both sides, it could be easy to create a current that pulls the water across the fins, creating a laminar flow everywhere but directly under the jet nozzle. That means that everywhere but where the nozzle is (a very small percentage of the actual fin-space) and the immediately surrounding areas, the fins are doing very little to aid with cooling as they get a boundary layer formed over them.

For the 49 micro fins and great turbulence creation, you have to give EK some credit – the block could certainly cool well, at least directly over the die. However, the lack of efficient exit methods would be where I might look for improvement. Sealing off the side of the fins that are right by the outlet would cause the water to flow out and around, which could make for better cooling, and it shouldn't add to the pressure drop greatly.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.